Written by Laura N.

1. Introduction

Multinational enterprises (MNEs) rely on various sources of competitive advantage to support their international expansion (Asmussen and Foss, 2014). Supply chain effectiveness is one of the key prerequisites for the sustainability of global operations, which makes this factor one of the primary sources of competitiveness. Modern multinational companies are becoming highly dependent on the quality of their supply chains management due to the growing globalisation of their operations and the need to succeed in a variety of developing markets with various customer needs and legislative environments (Kiessling et al., 2014). However, the role of this element in MNE operations and achieving a sustainable competitive advantage in foreign markets has not been extensively studied. The aim of this essay is to evaluate how supply chains can serve as a source of competitive advantage for MNEs.

2. The Relevance of Supply Chain Management to Modern Multinational Organisations

Global supply chain management is a relatively new field of study as this sphere is still being developed and is subject to ongoing legislative and structural changes (Sarfaty, 2015). Hence, traditional models may need adjustment to be effective for analysing the multinational context of business operations. The supply chain framework developed by Arway (2013) suggested that supply networks included raw material suppliers, manufacturing plants, distribution centres and retailers or end customers. At the same time, in the case of multinational organisations and perishable goods, some of these elements can be arranged differently on a geographical scale. For example, manufacturing activities for some product groups can occur within the country of their retail distribution while other goods can be imported from different countries (Grainger, 2016). Therefore, the choice of supply chain arrangements is dictated by the economies of scale and customer needs rather than traditional structural arrangements.

A good example of this idea implementation is the supply chain management approach of Carrefour and Walmart (Xu et al., 2014). These two organisations establish direct contacts with local manufacturers to streamline their operations and bypass middlemen. Afterwards, the goods are packed at their own facilities and are distributed to retail stores using a fully owned fleet of vehicles. At the same time, this strategy requires substantial investments to build a fully integrated supply chain and create local distribution centres in places where logistics systems and transportation systems are poorly developed (Kiessling et al., 2014). Nevertheless, this approach may not be applicable to all contexts because of region-specific legislative constraints (Venkata and Ravilochanan, 2014). On the one hand, multinational companies provide extensive employment opportunities and contribute to the well-being of their supply chain workers. On the other hand, their sales activities are often viewed as harmful to local retailers and are frequently limited (Yumas et al., 2016). This fact reduces the competitive benefits gained from localising some elements within the network.

Contemporary supply chains of multinational companies such as Tesco frequently depend on the integration of modern technologies and the development of partnerships with technology-intensive organisations (Zhao and Priporas, 2017). As the providers of raw materials and the facilities necessary to transform them into final products are often situated in different locations, this makes supply chain management a highly complicated activity. Therefore, multinational firms need to be capable of coordinating a vertically integrated supply chain in a cost-effective manner while maintaining proper compliance with applicable legislation. Overall, the analysis of Tesco, Walmart and other MNEs by Omondi and Namusonge (2015) identified that their supply chains included purchasing, logistics, manufacturing and marketing operations that were frequently decentralised and controlled by the ‘core company’. This suggests that one of the main problems encountered by these organisations is the capability to control and manage multiple processes occurring in different countries and time zones to achieve sustainable competitive advantage.

Managing multiple processes in different countries is especially important for companies that build the schemes different from traditional structural arrangements (Grimes and Sun, 2016). Such innovative organisations as Apple and Sony outsource a large share of production operations and integrate their supply and demand chains. This action substantially increases the complexity of their monitoring and control operations (Zhao and Priporas, 2017). These companies effectively become supply chain ‘coordinators’ rather than traditional ‘full-cycle’ structures and use their technological competence, customer knowledge, strategic partnerships and marketing expertise to create the products that are later produced by other companies including Foxconn (Grimes and Sun, 2016). In this case, competitive benefits arise from the core competencies of Apple and Sony while supply chain partners are selected on the basis of their pricing policies and technological resource availability (Park, 2014).

3. The Impact of Supply Chains Effectiveness on Competitive Advantage

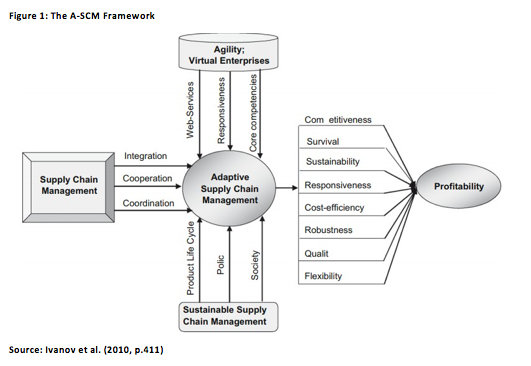

The A-SCM framework developed by Ivanov and Sokolov (2014) suggests that supply chain effectiveness contributes to organisational competitiveness from three main perspectives.

Firstly, supply chain management includes the cooperation, coordination and integration of individual supply chain nodes to achieve economies of scale. Secondly, sustainability principles ensure the compliance of organisational policies with society regulations and allow companies to make effective product life-cycle decisions (Ashenafi and Rao, 2014). Thirdly, supply chain agility is responsible for greater integration with online resources to increase firms’ responsiveness to consumer needs and market trends and ensure that their core competencies reflect the demands of the targeted markets (Ivanov and Sokolov, 2014). These three groups of factors make supply chain management highly adaptive and result in increased competitiveness in the form of higher responsiveness, flexibility, quality, cost-efficiency, sustainability and effectiveness that create better profitability.

The relevance of supply chain operation adaptability was also noted by Arasa et al. (2016). The researchers discovered that modern business environments were characterised by high degrees of instability and required high adaptability and flexibility from modern organisations (Arasa et al., 2016). Hence, companies need to be aware of new trends and consumer needs and have well-developed supply chains capable of providing a quick response to such changes. At the same time, the competitive advantage of multinational enterprises is directly associated with the resource-based choices and the selection of competitive strategies (Linneberg and Thorup-Jensen, 2014). In terms of resources, supply chains can be focused on the generation of unique or inimitable products, the achievement of sustainable economies of scale or the transfer of specific resources within the supply chain from the zones of lower productivity to high productivity areas. It should be noted that the multinational character of operations makes it easier to achieve sustainable competitive advantage through effective resource combination and management (Yumas et al., 2016).

The capability of supply chain management to generate competitive advantage also depends on the selected competitive strategy (Sillanpaa and Sillanpaa, 2014). The majority of MNEs adhere to the cost leadership strategy and have to maximise economies of scale and vertical integration in order to offer the lowest prices for non-unique products. In this case, the proper functioning of their supply chains is critical for achieving this objective as they need to purchase raw materials at the lowest price possible, transport them to the processing facilities and deliver to the point-of-sale in the most efficient manner (Sarfaty, 2015). At the same time, this strategy may also involve business communication and cooperation when foreign direct investments are not possible and MNEs have to work through local partners to comply with applicable legislative provisions (Yumas et al., 2016). In such situations, competitive advantage is generated by their capability to coordinate supply chain partners and ensure that their operations are effective and sustainable.

This standpoint is especially important within the scope of the brand management perspective (Aserkar et al., 2014). As the products created by a highly decentralised supply chain are usually presented under a single ‘umbrella brand’, the coordination between individual companies and supply chain nodes is critical for ensuring the positive reputation of the MNE in general. Otherwise, the competitiveness of the brand will be undermined as in the case of Walmart goods availability problems or Colgate-Palmolive operational efficiency issues. An important aspect of the supply chain competitive potential was noted by Ashenafi and Rao (2014) who stated that supply chain structures were evolving from the hierarchical design towards the market-driven design. Traditional manufacturing and distribution processes were built on the basis of frameworks similar to the one described by Arway (2013). In turn, modern multinational environments frequently base structural decisions on the needs of end consumers and the availability of resources in different regions.

4. Conclusion

It can be concluded that multinational companies are becoming progressively more decentralised in terms of their internal structures (Asmussen and Foss, 2014). Therefore, the proper management of supply chains and the coordination of supply chain partners are critical for achieving good responsiveness to customer needs and supplying the most demanded products to the right markets in a timely manner. As modern markets are often characterised by legislative hindrances and severe competition with local companies, multinational organisations have to be highly effective in selecting optimal competitive strategies and resource management solutions to achieve a sustainable competitive advantage (Sarfaty, 2015). That said, supply chains need to be customer-centric rather than hierarchical to achieve good adaptability and flexibility (Ivanov and Sokolov, 2014). Otherwise, competitive advantage would not be sustainable as the instability of the contemporary business environment requires high responsiveness from MNEs.

References

Arasa, R., Mwaura, R. and Ngui, R. (2016) “The Relationship between Supply Chain Strategies and Achievement of Competitive Advantage in Seed Manufacturing Companies in Nairobi County, Kenya”, International Journal of Science and Research, 5 (1), pp. 358-364.

Arway, A. (2013) Supply chain security: A comprehensive approach, London: CRC Press.

Aserkar, R., Kumthekar, N. and Aserkar, S. (2014) “Investigating the Link between Supply Chain Performance and Brand Performance”, International Journal of Humanities and Social Science, 4 (9), pp. 228-242.

Ashenafi, B. and Rao, M. (2014) “Supply Chain Management for Sustainable Competitive Advantage”, Journal of Business Management & Social Sciences Research, 3 (2), pp. 88-94.

Asmussen, C. and Foss, N. (2014) “Competitive advantage and the existence of the multinational corporation: Earlier research and the role of frictions”, Global Strategy Journal, 4 (1), pp. 49-54.

Grainger, A. (2016) “Customs management in multinational companies”, World Customs Journal, 10 (2), pp. 17-35.

Grimes, S. and Sun, Y. (2016) “China’s evolving role in Apple’s global value chain”, Area Development and Policy, 1 (1), pp. 94-112.

Ivanov, D. and Sokolov, B. (2014) Adaptive Supply Chain Management, Berlin: Springer Science & Business Media.

Ivanov, D., Sokolov, B. and Kaeschel, J. (2010) “A multi-structural framework for adaptive supply chain planning and operations control with structure dynamics considerations”, European Journal of Operational Research, 200 (1), pp. 409-420.

Kiessling, T., Harvey, M. and Akdeniz, L. (2014) “The evolving role of supply chain managers in global channels of distribution and logistics systems”, International Journal of Physical Distribution & Logistics Management, 44 (8), pp. 671-688.

Linneberg, M. and Thorup-Jensen, L. (2014) “Towards strategic CSR in multinational corporations”, Danish Journal of Management & Business, 2 (1), pp. 37-51.

Omondi, D. and Namusonge, G. (2015) “The Role of Supply Chain Leadership in Retail Institutions’ Performance: The Case of Nakumatt Holdings Limited, Kenya”, International Journal of Humanities and Social Science, 5 (2), pp. 135-142.

Park, Y. (2014) “Integration of Supply and Demand Chain in Emerging Markets”, Journal of Business and Economics, 5 (12), pp. 2282-2293.

Sarfaty, G. (2015) “Shining light on global supply chains”, Harvard International Law Journal, 56 (1), pp. 419-463.

Sillanpaa, I. and Sillanpaa, S. (2014) “Supply Chain Strategy: Empirical Case Study in Europe and Asia”, Management, 9 (2), pp. 95-115.

Venkata, R. and Ravilochanan, P. (2014) “The role of supply chain management on organized and unorganized grocery retailers – A review on Indian perspective”, Asian Social Science, 10 (22), pp. 1-16.

Xu, L., Xu, Q. and Liu, X. (2014) “Wal-Mart and Carrefour’s supply chain management strategies in China”, International Journal of Business and Management, 9 (7), pp. 155-161.

Yumas, S., Primiana, I., Cahyandito, M. and Kaltum, U. (2016) “New Model of Competitive Advantage of Supply Chain Management Practices: A Case of Indonesian Cacao Manufacturing Industry”, International Journal of Economics, Commerce and Management, 4 (9), pp. 407-422.

Zhao, S. and Priporas, C. (2017) “Information technology and marketing performance within international market-entry alliances: A review and an integrated conceptual framework”, International Marketing Review, 34 (1), pp. 5-28.